Since 1964

Anritsu developed and sold its first ever Checkweigher in 1964 to a Pharmaceutical company. Learning from the pharmaceutical industry’s rigorous attitude toward quality control, Anritsu Infivis has since continued to develop its technologies. Anritsu Infivis is committed to addressing advanced quality assurance issues through closer cooperation with customers and partners in the pharmaceutical industry. Ever since, Anritsu has installed over 80.000 units of Pharmaceutical Checkweighers, 50.000 units of Metal Detectors and 10.000 units of X-ray allover the world placing her as the leader in the industry.

Anritsu Pharmaceutical Metal Detector detects metal contaminants in all pharmaceutical applications.

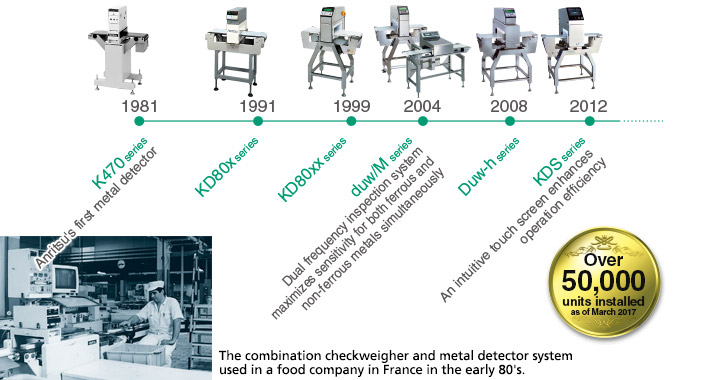

Anritsu designs and develops all its products in-house since 1981.

Anritsu has developed metal detectors using magnetic sensing technology in 1981. Since then, we manufactures metal detectors for over 30 years and its cumulative sales have reached over 50,000 units (as of March 2017).

Anritsu’s innovative M6 metal detector is now available in large format.

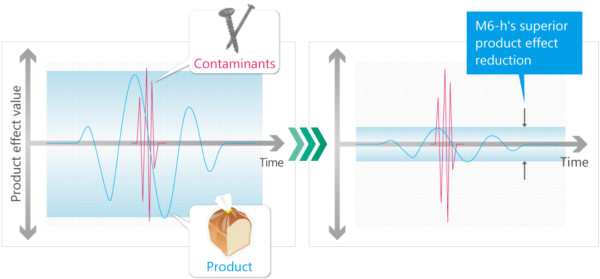

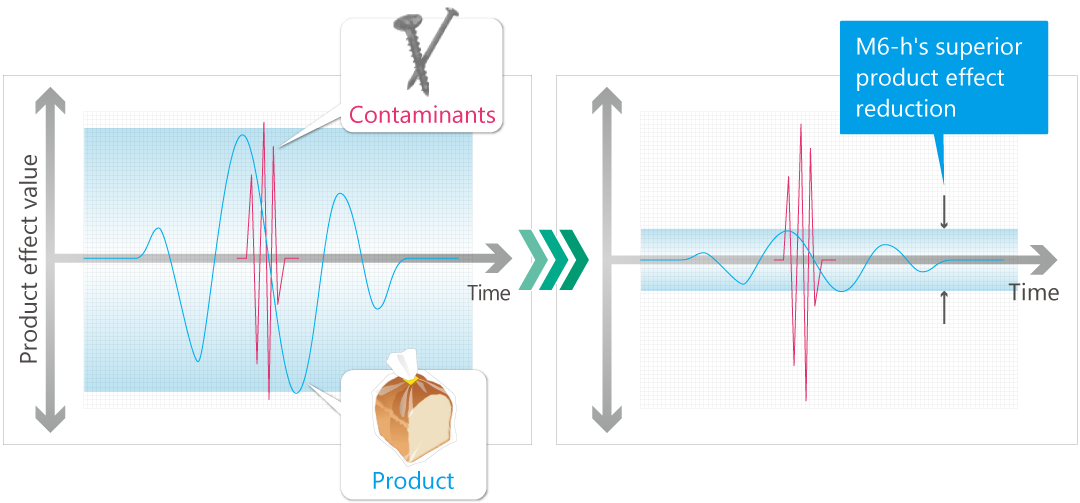

High detection sensitivity and stability

Built-in digital signal processing (patent pending) better isolates product effect and minimizes its impact on detection, resulting in outstanding performance. Advanced Digital Signal Processing.

Repeatable, reliable performance

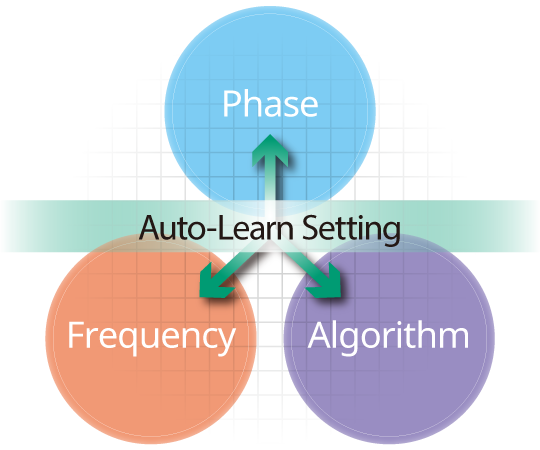

The auto-learn process optimizes the best phase, frequency and detection algorithm for the dual simultaneous frequencies.

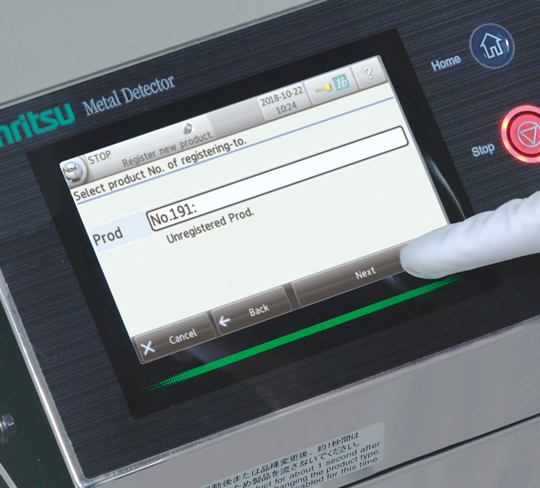

Intuitive operation

The 7-inch wide color touchscreen provides easy operation. Clear graphical guidance enables users to work efficiently.

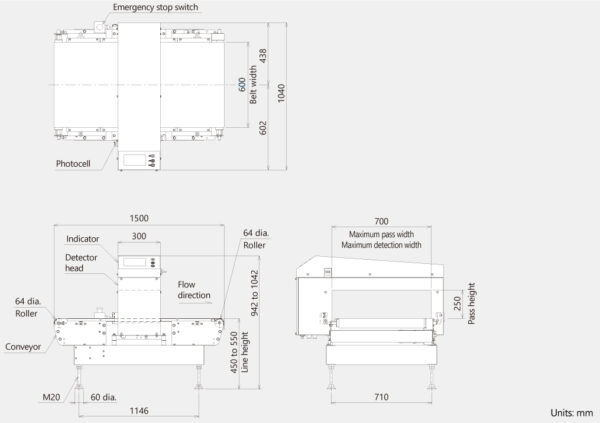

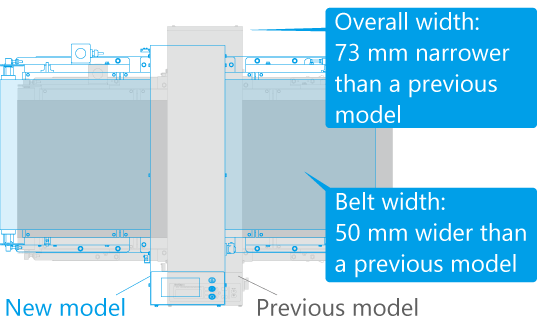

Compact design with inspection flexibility for a wide range of products

With a conveyor width of just 700 mm, the M6-h gives you more usable inspection area than the previous model.

Aperture heights range between 50 mm and 400 mm, and conveyors are available in lengths of 1200 mm, 1500 mm, and 1800 mm.

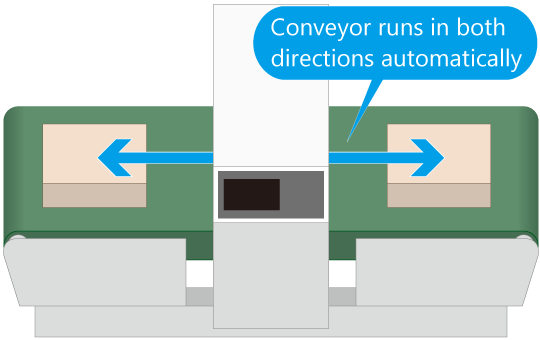

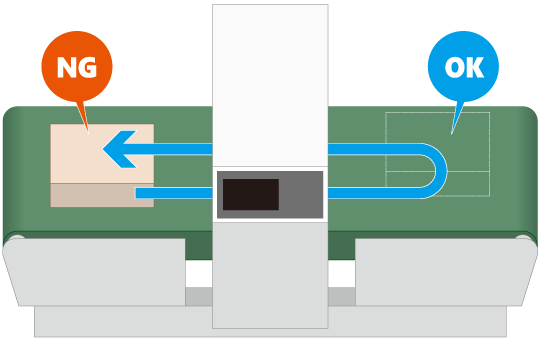

Reverse operation to reduce operator workload

Back & Forth feature makes new product setup easier by repeatedly feeding during auto-learn.

The optional reverse rejection feature allows no-good product handling without a dedicated rejection unit.

Back-and-forth auto-setting Reverse rejection (Optional)

Designed with safety and hygiene in mind

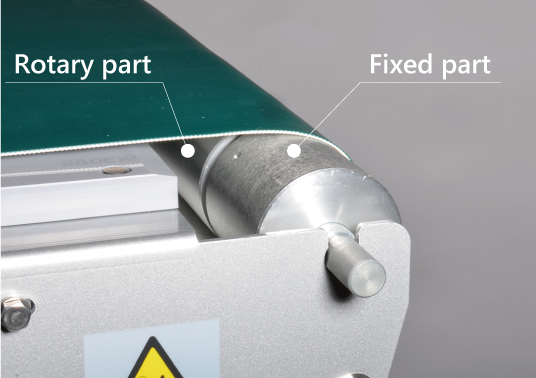

Pinch point prevention:

Superior hygiene:

Tool free belt removal:

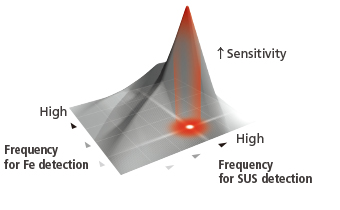

Industry leading detection

High sensitivity and High stability

Anritsu’s unique dual-frequency system

Anritsu’s proprietary dual-frequency design determines the optimal settings to maximize sensitivity for both ferrous and non-ferrous metals. Since metals respond differently to different magnetic field frequencies, it is difficult for conventional single frequency systems to detect both ferrous and non-ferrous metals. Anritsu has patented a dual-frequncy inspection system, which automatically determines the best frequencies to maximize sensitivity for both ferrous metals simultaneously. Stainless steel fragments dropped from a production equipment can be also detected.

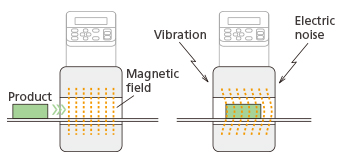

Heads are vibration and electric noise resistant

Metal detectors look for fluctuations with magnetic fields when product passes through the detector head. Since the magnetic fields are affected by external sources such as floor vibration and inverters from nearby machines, a metal detector must be designed to handle these challenges. With this in mind, Anritsu’s detection heads were designed to provide high sensitivity without sacrificing repeatability and reliability.