Since 1964

Anritsu developed and sold its first ever Checkweigher in 1964 to a Pharmaceutical company. Learning from the pharmaceutical industry’s rigorous attitude toward quality control, Anritsu Infivis has since continued to develop its technologies. Anritsu Infivis is committed to addressing advanced quality assurance issues through closer cooperation with customers and partners in the pharmaceutical industry. Ever since, Anritsu has installed over 80.000 units of Pharmaceutical Checkweighers, 50.000 units of Metal Detectors and 10.000 units of X-ray allover the world placing her as the leader in the industry.

Anritsu Pharmaceutical Metal Detector detects metal contaminants in all pharmaceutical applications.

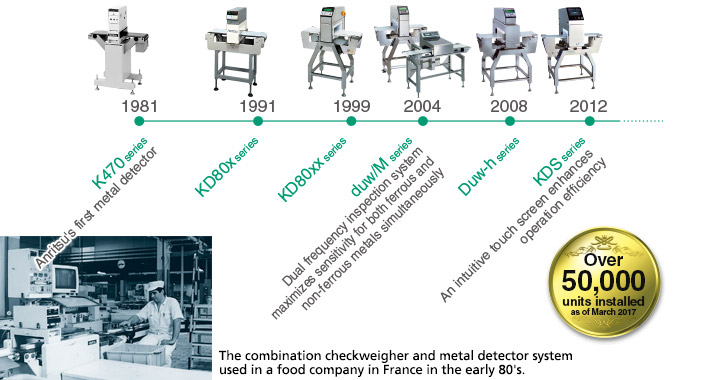

Anritsu designs and develops all its products in-house since 1981.

Anritsu has developed metal detectors using magnetic sensing technology in 1981. Since then, we manufactures metal detectors for over 30 years and its cumulative sales have reached over 50,000 units (as of March 2017).

Enhanced Performance M6-h delivers high detection sensitivity and stability on your production line–

Simplified operation. Equipped with the stabilizing technology, HRDSP

Comfortable operation

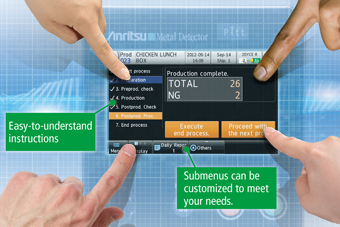

7 inch wide color TFT LCD display for an operation screen.

Instructions are displayed concisely on a touch panel screen during production, ensuring proper proceedings even when the shift changes. You can select and rearrange frequently used items to be displayed on submenus.

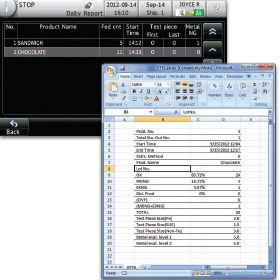

Daily reports are displayed on an operation screen to monitor the inspection status at any time. The data can be transferred to a PC via USB/Ethernet for enhanced quality control..

Smart Guide ensures correct operation checking

Metal detectors are considered a critical control point (CCP) in HACCP programs and continuous operation checking is required to meet standards. Smart Guide navigates operation check and maintenance procedures in an easy-to-understand format. When a procedure was performed incorrectly, it will not allow to proceed further, ensuring correct operation management. The time and costs for training operators can be minimized.

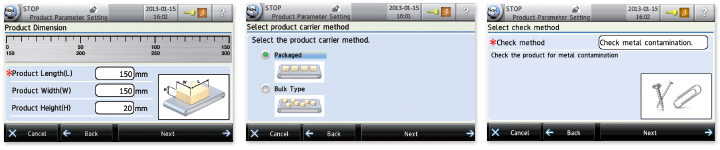

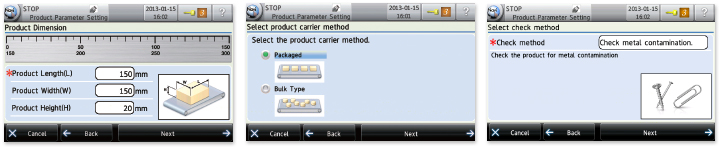

Product Registration Navigation

Product Registration Navigation simplifies parameter setting procedures with step-by-step illustrated instructions. You can save time and effort on reading through operation manuals or putting together training documents.

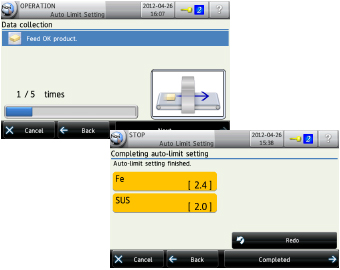

Optimal sensitivity achieved by HIS (High Sensitivity) Setting

HIS (High Sensitivity) setting automatically analyzes product and contaminant properties and sets detection limits precisely for optimal contaminant detection.

A simple step-by-step procedure

Anyone can configure the HIS setting by feeding OK products and test pieces with step-by-step instructions.

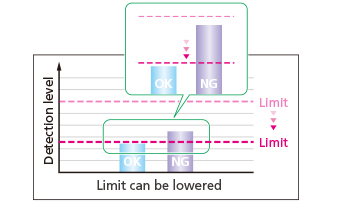

Auto-limit function and Auto-tracking function for enhanced stability

Anrtisu metal detector prevents false rejects by Auto-limit function and Auto-tracking function, supporting stable production at your facility.

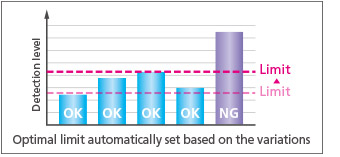

Auto-limit function:

This function assures stable inspection by automatically setting the optimum judgment limit based on changes in effect values of products and test pieces.

Auto-tracking function:

Anritsu metal detectors’ auto setting function automatically determines the best evaluation timing (this timing is called phase). However, phase shift caused by product effect can trigger false rejects. Auto-tracking functions compensate phase shift by following the change of product effect, preventing false rejects.

*Auto-tracking functions are automatically set by auto-setting.

Industry leading detection

High sensitivity and High stability

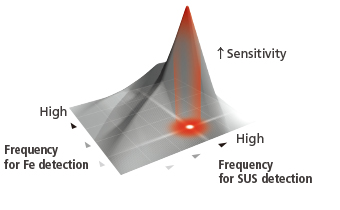

Anritsu’s unique dual-frequency system

Anritsu’s proprietary dual-frequency design determines the optimal settings to maximize sensitivity for both ferrous and non-ferrous metals. Since metals respond differently to different magnetic field frequencies, it is difficult for conventional single frequency systems to detect both ferrous and non-ferrous metals. Anritsu has patented a dual-frequncy inspection system, which automatically determines the best frequencies to maximize sensitivity for both ferrous metals simultaneously. Stainless steel fragments dropped from a production equipment can be also detected.

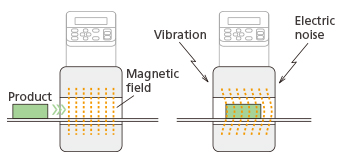

Heads are vibration and electric noise resistant

Metal detectors look for fluctuations with magnetic fields when product passes through the detector head. Since the magnetic fields are affected by external sources such as floor vibration and inverters from nearby machines, a metal detector must be designed to handle these challenges. With this in mind, Anritsu’s detection heads were designed to provide high sensitivity without sacrificing repeatability and reliability.